Sewon Q&TECH

Product

Sewon is the world's best company and will manage the world.

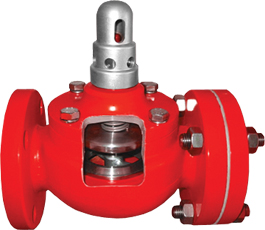

Flame Arrester

For your safety, choose our products.

SEWON has been developed so many kinds of flame arrester including detonation type as a safety device for plants and vessels.

Flame arrester is to protect the safety equipment from flame, by being equipped into the pipe lines, gas duct lines and vent lines of the tank where

inflammable gas is stored, and is a very important device to prevent the flame occurred due to explosion, and ignition that is happened when inflammable

gas is changed up to the temperature of flashing point owing to the influence of operation of equipment or surrounding environment, etc..

There are several types of flame arrester such as crimped ribbon arresters, parallel plate arresters, pebble arresters, hydraulic arresters, wire screen

arresters, wire packed arresters and sintered arresters, but crimped ribbon arresters are most commonly used. Each type has its own characteristics

and they are not necessarily all suitable for the same service.

SEWON crimped metal flame arresters are safety devices designed to stop the propagation or spread of flames through flammable gas or vapor mixtures

in pipelines. They prevent flame entering or leaving plant and can confine flame propagation to within certain equipment. Flame arresters are passive

devices,

operating automatically and normally have no moving parts.

When gas or vapor mixtures ignite, flame arresters prevents further propagation by absorbing and dissipating heat from the burning gas or vapor

on one

side of arresters lowering the temperature of the combustion products to below the auto ignition point of the gas on the opposite side.

This is achieved as the hot gasses give up their heat to the cell walls on passing through the crimped metal arrester element.

Critical infomation needed for. the proper application of flame and detonation arresters

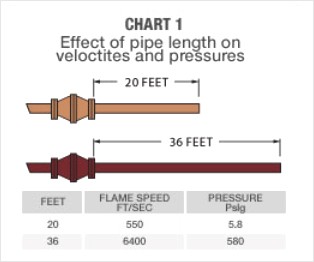

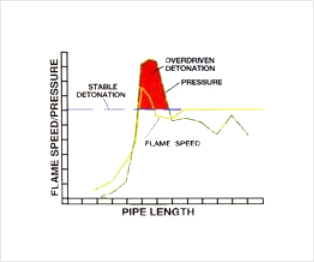

Chart 1shows the effect of increases in pipe length on flame front speed and pressure. A 4.3% propane/air mixture is ignited in a 2" pipe.

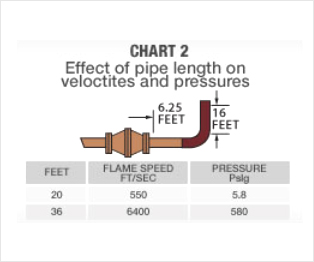

20 feet of straight 2" pipe produces a flame speed of 550 feet per second.

When this piping length is increased to only 36 feet, a flame speed of 6400 feet per second is recorded. This is a clear detonation(the movement of

a flame through a gas or vapor within a medium at the speed of sound in that medium). A standard vent-line/in-line flame arrester can be rendered

ineffective.

For a 4.3% propane/air mixture, the stable detonation velocity is 5800 feet per second.

As pipe length increases, flame speeds measured at the arrester increase.

For a specific and narrows range of pipe lengths, pressures and velocities in excess

of those associated with stable detonation are encountered.

This is knows as an overdriven detonation devices in this overdriven range to verify

their effectiveness.

Any irregularities in the piping configuration (bends, changes or obstructions) tend to

increase the turbulence in the unburned vapors. Because turbulence provides the

mechanism for acceleration of the flame font, such irregularities result in higher flame speeds.

As we see in Chart2, 6.25 feet of straight piping will yield a flame speed of 180 feet per second. Introduction of only 90 degree bend and 16 feet of

straight piping accelerates the flame front to a detonation. Not taking these bends, irregularities or obstructions into consideration can easily lead

to a misapplication of the arrester.

Chemical Classifications

In the National Electric Code (see Table 1), chemicals are grouped according to their burning and explosion characteristics. The classifications

consider the MESG-Maximum Experimental Safe Gap (see Glossary of Terms for definition), maximum explosion pressure, and minimum ignition

temperature of the specific gas or vapor.

The categories recognized are Group A, B, C, and D. Group D atmospheres represent the least volatile flammable atmospheres, and the chemical

are represented as progressively more volatile through Groups C, B and A respectively. The stable detonation velocities and quenching diameters

of some of the common chemicals identified as representing Groups A, B, C and D are shown in the following table :

| Gas | Group | Quenching Diameter | Detonation Velocity |

|---|---|---|---|

| methane | D | 0.145 inches | 5800 FT/S |

| propane | D | 0.105 inches | |

| butane | D | 0.110 inches | |

| hexane | D | 0.120 inches | 700 FT/S |

| ethylene | C | 0.075 inches | |

| hydrogen | B | 0.034 inches | |

| acetylene | A | 0.005 inches |

Table 1 Chemicals by groups

| Gas | Chemical |

|---|---|

| Group A | acetylene |

| Group B | butadiene, ethylene oxide, hydrogen, manufactured, gases containing, more than 30%, hydrogen(by volume), propylene oxide |

| Group C | acetaldehyde, cyclopropane, dietyl ether, ethylene, unsymmetrical, dimethyl hydrazine |

| Group D |

acetone, acrylonitrile, ammonia, benzene, butane, 1-butanol(butyl alcohol), 2-butano(secondary butyl alcohol), n-butyl acetate, isobutyl acetate, ethane, ethanol(ethyl alcohol), erthyl acetate, ethylene dichloride, gasoline, heptanes, hexanes, isoprene, methane(natural gas), methanol(methyl alcohol), 3-methyl-1-butanol(isoamyl alcohol) methyl isobutyl, ketone, 2-methyl-1-propanol(isomyl alcohol), 2-methyl-2-propanol(tertiary butyl alcohol), petroleum naptha, octanes, 1-pentanol(amyl alcohol), propane, 1-pentanol(amyl alcohol), 2-pentanol(isoamyl alcohol), propylene, styrene, toluene, vinyl acetate, vinyl chloride, xylenes |

Only proper testing of flame arresters and detonation arresters can qualify their design and effectiveness within a particular chemical group.

An arrester tested with a Group D vapor is considered to be suitable for use with other Group D atmospheres and pressures are comparable.

Note, however, that an arrester tested with a Group D chemical is not necessarily suitable for use with Group C, B, or A chemicals.

Arresters tested with a higher level chemical group are generally acceptable for use with lower level groups (a Group C arrester would be suitable

for a Group D service) but should not necessarily be considered to be suitable for use with higher level groups

(a Group C arrester should not be assumed to be suitable for use in a Group B service).

How to order

| MODEL | SIZE | MATERIALS | FLANGE DRILLING | OPTION |

|---|---|---|---|---|

Body / Flame Element |

||||

| SFC SFG SFE SFH SFO SFD SFJ SFK SFL |

A1 : 1/2" A2 : 3/4" 01 : 1" 1A : 1-1/2" 02 : 2" 2A : 2-1/2" 03 : 3" 04 : 4" 06 : 6" 08 : 8" 10 : 10" 12 : 12" SS : Special |

C : Carbon Steel 4 : 304 S.S 5 : 304L S.S 6 : 316 S.S 7 : 316L S.S A : Aluminum H : Hastelloy L : Alloy 20 S : Special Material |

AR : ASME Class 150 RF AF : ASME Class 150 FF KR : KS/JIS 10K RF KF : KS/JIS 10K FF NO : NO Drilling SS : Special |

O : No Option J : Steam Jacket T :Temperature Monitoring Sensor (Unprotected side only) B : Temperature Monitoring Sensor (Both sides) S : Special |

Example

Means a 8" model SFG with 304 stainless steel body, 316L stainless steel flame element,

ASME Class 150 RF flange drilling and no other option.